Our Products

Niobium

Niobium has been designated as “critical” by the US Government because of its many uses in essential civilian and defense technologies, and because its supply chains are highly limited. The US produces no primary niobium and imports 100% of the niobium we need. This is one reason why the Elk Creek Critical Minerals Project is to strategic for the US.

Niobium has been designated as “critical” by the US Government because of its many uses in essential civilian and defense technologies, and because its supply chains are highly limited. The US produces no primary niobium and imports 100% of the niobium we need. This is one reason why the Elk Creek Critical Minerals Project is to strategic for the US.

When added to steel, Niobium makes an alloy that is stronger, lighter in weight, and highly resistant to corrosion. These steel alloys are known as High Strength, Low Alloy steels (HSLA).

Consumption of HSLA steel has steady increased over the past two decades because of its ability to:

- Strengthen buildings and other mega-structures;

- Increase the lifespan of bridges and infrastructure projects;

- Ensure that pipelines operate safely;

- Increase both the safety of cars and trucks and lightweight them, increasing range and fuel economy and reducing air emissions;

- And many others.

Niobium is added to steel in the form of ferroniobium, which is a mixture of 65% niobium and 35% iron. This is the form of niobium that NioCorp intends to produce at our Elk Creek Project. Ferroniobium represents over 90% of world niobium production. For many applications, such as super alloys and oil and gas pipelines steels, there are no effective substitutes for niobium.

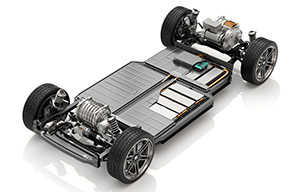

Niobium has a wide variety of other uses, including as a critical component in niobium-lithium-ion batteries, which are now progressing rapidly to commercialization. These batteries have been shown to significantly increase the range of electric vehicles, dramatically reduce charge times, and virtually eliminate the fire and explosion hazards of standard lithium-ion batteries.

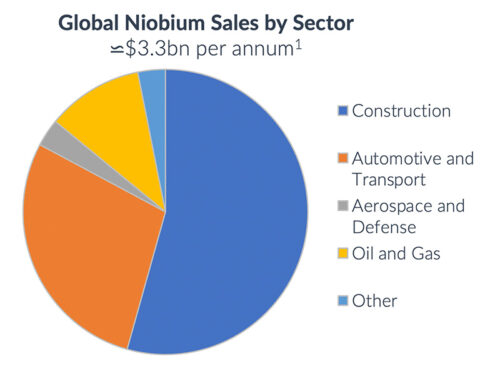

The following shows the major industrial sectors that rely on Niobium:

Source: CBMM, 2022

Facts About Niobium and its Markets

- 88% of the world’s Niobium is produced in only one country – Brazil – which increases supply chain risk and has forced the US Government to stockpile Niobium.

- Growth of the global Niobium market is expected to rise sharply with the expected use of niobium in niobium-lithium-Ion batteries, which enables faster battery charging and longer range for electric vehicles.

- Lightweighting of transportation systems and strengthening of bridges and mega-infrastructure projects is also expected to drive additional long-term growth for Niobium.

- Niobium has a highly liquid global market with many users and a growing number of applications.

Powerful Steel Strengthener

Niobium is integral to making stronger and lighter steels for buildings & infrastructure mega-projects. How powerful is Niobium? Only 0.025% Niobium in the steel of the Millau Viaduct bridge in the south of France reduced the weight of steel and concrete in the project by 60%, significantly reducing air emissions in the construction phase.

Key to Lightweighting

Growing demand for lighter weight and more fuel-efficient cars and trucks is increasing demand for Niobium. How effective is Niobium in light-weighting vehicles? Just 300 grams of Niobium reduces the weight of mid-size car by 200 kilograms and increases fuel efficiency by 5%. That increased efficiency significantly reduces per-mile vehicle air emissions.

Growing Market Demand

Niobium is a critical ingredient in niobium-lithium-Ion batteries. This technology has been shown to allow EV batteries to fully re-charge in 10 minutes or less and can extend battery life by 5x. These batteries also eliminate the fire or explosion hazard that is present with current Li-Ion batteries.

Niobium: Element 41

|

Name |

Niobium |

|

Atomic Number |

41 |

|

Element Classification |

Metal |

|

Phase at Room Temp. |

Solid |

|

Melting Point |

2750 K (2477°C or 4491°F) |

|

Boiling Point |

5017 K (4744°C or 8571°F) |

|

Density |

8.57 grams per cubic centimeter |

To learn more about the element Niobium, please see the Royal Society of Chemistry’s Niobium page here.

Connect with us socially!